The Titanium Nuts Factory: Innovation and Quality in Manufacturing

When discussing industrial manufacturing, titanium nuts factories occupy a unique and vital place. Producing high-performance fasteners, these factories are essential in various sectors, including aerospace, automotive, and construction. In this article, we will explore the significance of titanium nuts, the advantages they offer, and the processes that define the operations of a titanium nuts factory.

What Makes Titanium an Exceptional Material?

Titanium has garnered immense popularity in the manufacturing sector due to its remarkable properties. Here are some key attributes of titanium:

- High Strength-to-Weight Ratio: Titanium is renowned for being both lightweight and extremely strong, making it an ideal choice for applications where performance is critical.

- Corrosion Resistance: Titanium exhibits exceptional resistance to corrosion, ensuring longevity, especially in harsh environments.

- Biocompatibility: This property makes titanium a preferred material in medical applications, particularly in implants.

- High Melting Point: Titanium's ability to withstand high temperatures without degrading adds to its versatility.

The Role of Titanium Nuts in Various Industries

Titanium nuts are not just fasteners; they play a crucial role in ensuring the integrity and reliability of structures and vehicles. Here’s a closer look at their applications across different fields:

Aerospace Industry

In the aerospace sector, the demand for lightweight and strong components is paramount. Titanium nuts are extensively used in aircraft assemblies, where they help enhance fuel efficiency and overall performance while ensuring safety and durability.

Automotive Sector

Similarly, in automotive manufacturing, titanium nuts contribute to reducing vehicle weight, hence improving fuel economy. They are also used in high-performance vehicles where strength and performance is of utmost importance.

Construction and General Contractors

General contractors benefit from using titanium nuts in building structures that require durable and reliable fastening solutions, especially in environments exposed to moisture and harsh conditions.

Medical Applications

In the medical field, titanium is preferred for surgical implants and tools because of its biocompatibility and strength. Titanium nuts hold together surgical equipment and implants, ensuring they perform reliably over time.

Manufacturing Processes in a Titanium Nuts Factory

The manufacturing processes in a titanium nuts factory are intricate and high-tech, requiring specialized techniques to ensure precision and quality. Let's delve into the steps involved in producing titanium nuts.

1. Raw Material Selection

The journey begins with selecting high-quality titanium alloy, which is vital for ensuring the final product's performance. The titanium used usually comes in various grades, depending on the required properties for specific applications.

2. Forging and Machining

Once the raw material is secured, the next step is forging, where titanium is heated and shaped into rough forms. After forging, the nuts undergo machining processes, including turning and threading, to achieve precise dimensions and specifications.

3. Heat Treatment

Heat treatment is a crucial process that enhances the mechanical properties of titanium nuts. This step can involve processes like annealing or aging, which optimize the strength and ductility of the fasteners.

4. Quality Assurance

Quality control is paramount in a titanium nuts factory. Each nut produced undergoes rigorous testing to ensure they meet industry standards. This may include tensile testing, dimensional inspections, and corrosion resistance evaluations.

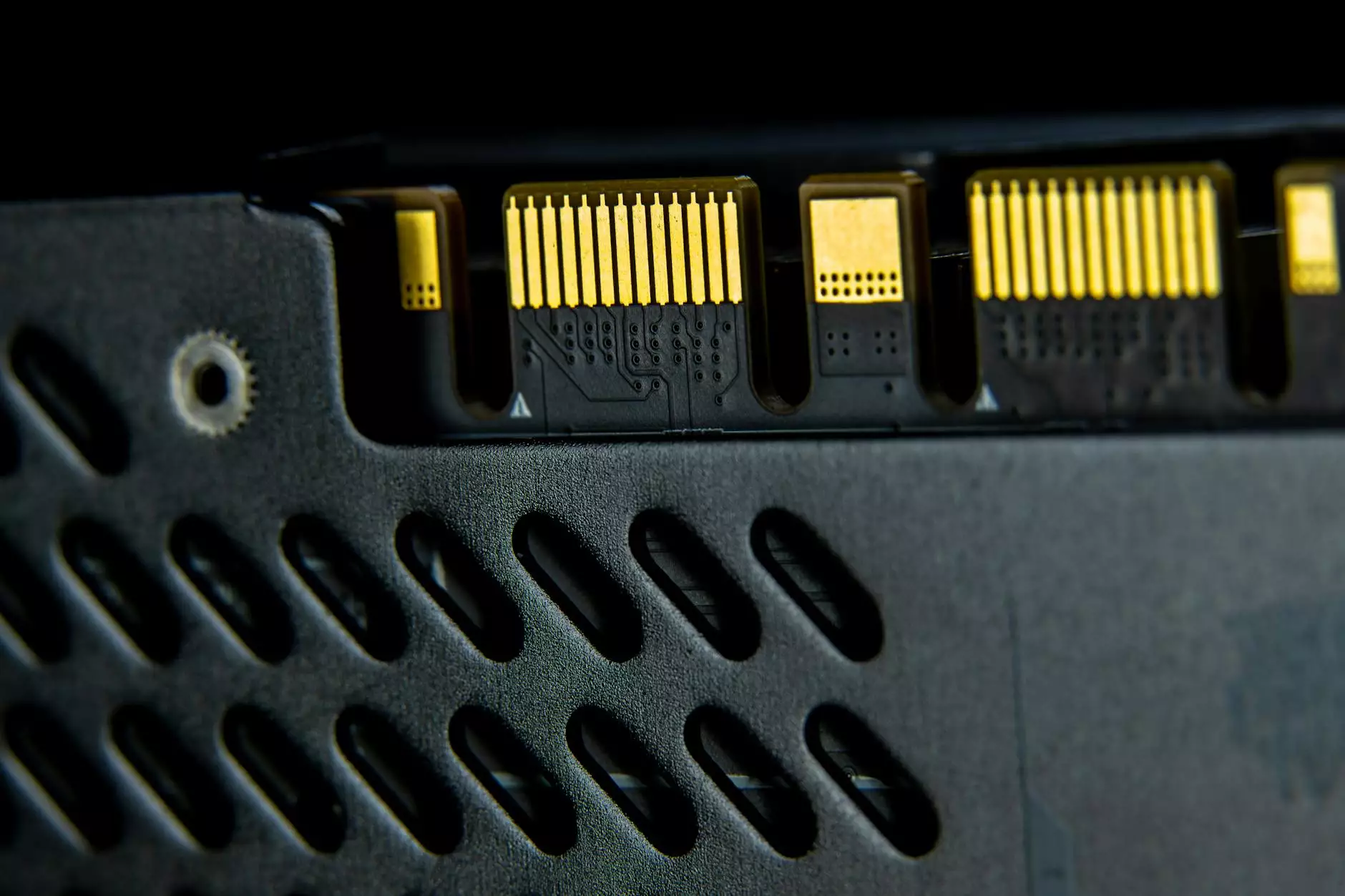

5. Surface Finishing

To improve durability and aesthetic appeal, titanium nuts are often subjected to various surface finishing treatments such as anodizing or coating. These treatments further enhance corrosion resistance and wear properties.

Benefits of Sourcing from a Titanium Nuts Factory

Choosing to source titanium nuts from a reputable factory brings a multitude of advantages:

- Quality Assurance: Products are manufactured under strict quality control processes, ensuring reliability.

- Custom Solutions: Many factories, including those servicing general contractors, offer customized products tailored to specific project requirements.

- Cost-Effectiveness: Although titanium may have a higher upfront cost, its durability and performance can lead to lower long-term costs due to reduced maintenance and replacement needs.

- Industry Expertise: Factories specializing in titanium nuts often have a wealth of experience and knowledge, allowing them to provide valuable guidance and recommendations.

Environmental Impact and Sustainability in Titanium Production

In recent years, there has been a growing focus on sustainability within the manufacturing sector. The titanium industry is no exception. Here are a few ways that titanium nuts factories are becoming more sustainable:

1. Recycling Titanium

Recycling titanium scrap from production processes significantly reduces waste and conserves natural resources. Many forward-thinking factories invest in systems to reclaim and reuse titanium chips and remnants.

2. Energy Efficiency

Modern manufacturing facilities are increasingly utilizing energy-efficient technologies and practices, reducing their carbon footprint and overall environmental impact.

Choosing the Right Titanium Nuts Factory

For general contractors and businesses in need of high-quality titanium nuts, selecting the right factory is crucial. Here are some tips to guide your choice:

- Evaluate Certifications: Ensure that the factory holds relevant industry certifications, which guarantee compliance with quality standards.

- Assess Production Capabilities: Look for a factory with the capacity to meet your specific quantity and customization needs.

- Check Reviews and References: Investigating customer feedback can provide insights into the factory’s reputation and reliability.

- Inquire About Support: A factory that offers excellent customer support can help resolve issues quickly and efficiently.

Conclusion

In conclusion, titanium nuts factories play an indispensable role in modern manufacturing, providing essential components that enhance the performance and safety of products across various industries. With the numerous benefits offered by titanium, including its strength, corrosion resistance, and lightweight properties, the significance of sourcing high-quality titanium fasteners cannot be overstated.

For businesses considering using titanium nuts, partnering with a reputable factory like titaniumbolts.com can streamline operations and ensure the integrity of projects. By understanding the intricacies of titanium manufacturing and the myriad advantages offered by titanium nuts, general contractors can make informed choices that positively influence their projects' outcomes.